Protein Application Center

General Short Description

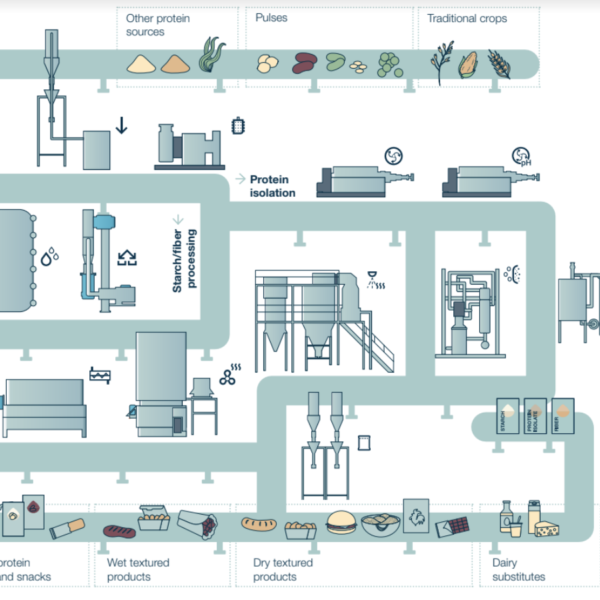

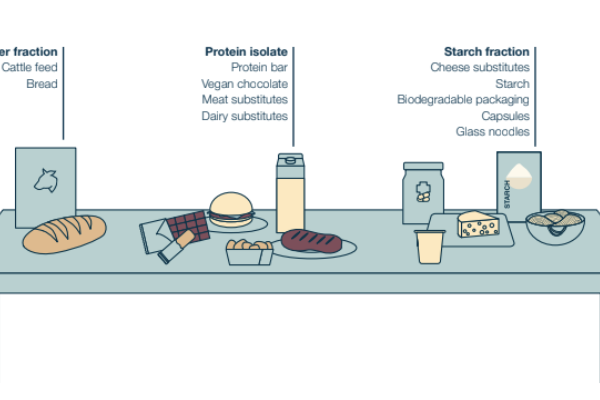

The Protein Application Center features an industrial pilot-plant production line as well as a batch-line for processing plant-based protein isolates, starch and fiber. The different plant sizes enables us to run trials with higher capacities on a continuous manufacturing process and smaller quantities that go through production process as a distinct unit. On the batch line, also dairy alternatives can be tested.

Relevant technical details

Scales of production :

- Small-scale but highly flexible batch line (including dairy processing for plant-based beverages)

- Industrial-size machines for easy scale up

Technology solutions available for protein isolation and sidestreams valorization :

- Wet milling or dispersing in water, depending on raw materials

- Decanter centrifuges for solid-liquid separation

- Membrane Separation Systems for protein fractionation (including micro-filtration, ultrafiltration, and reverse osmosis)

- Starch and fiber processing – including centrisieve, screw press, hydrocyclones, and a rotary vacuum filter

- Drying equipment – spray dryer and whirlflash dryer

- Highly flexible batch scale line with tabletop equipment – wet milling, decanter, membrane system, spray dryer, UHT line with homogenizer, fermentation unit, and extrusion system

Services:

- Process development and validation in the field of protein isolation and/or processing and related areas such as downstream processing of biological and biotechnological wet separation processes

Applications

- Support in feasibility trials and run optimizations

- Process adaptions for fast prototyping and proof of concept

- Different technological solutions for processing various product quantities

- Thorough process and product knowledge

- Analysis, creation, and sensory expertise to create winning products

Additional information

Around 200 kg/h infeed for yellow peas on continuous process line

– Around 1kg/h infeed on small batch scale line

– 300 m2 space to explore protein processing possibilities

For rental agreement, availability and pricing, please reach out to the contact person